In this section I will bend the ribs and linings and glue them to the mold.

The initial set of ribs I had selected and thicknessed to 1.5 mm didn’t work so I went to the woodpile and found something else. I set up the bandsaw for ripping ribs.

The piece has been cut to about 5 inches high and about 30 inches long. One side is run through my Inca 8 5/8 inch Jointer/Planer. Lovely tool... Every time I rip a rib, I run the main piece through the jointer so there is one side that is clean and smooth.

The next step is to don your dust mask, ear protection, and glasses. Turn on all the exhaust fans and set to it. Be careful, though. There are a lot of violin makers who are members of the “Stump Club”. Membership is gained through carelessness with this tool resulting in a lost digit. I don’t qualify. I cut a fingertip off with a chisel years ago and the good doctors sewed it back on.

Don’t push or you will burn the blade.

After dicing up the whole section into ribs, I take them into the garage for a session with my thickness sander. Next step is to scrape them smooth.

These pictures are actually of the failed ribs.

There is some block preparation that needs to be done. I’ve already traced the outline onto the blocks and cut them out with the bandsaw... just for the center bout and endblock at this time, though.

I have a sanding drum chucked up in the drill press to clean up the curvy bits.

The end blocks, I do by hand.

This is my bending setup. The linings have been precut and set aside to soak. I do not soak the ribs. I wet them prior to bending. I used to soak them, but I got some very strange warping. They ended up wavy. There are some thin aluminimum sheets that I use for backing when I bend a rib. The center bouts are first.

They are bent slowly and dried thoroughly.

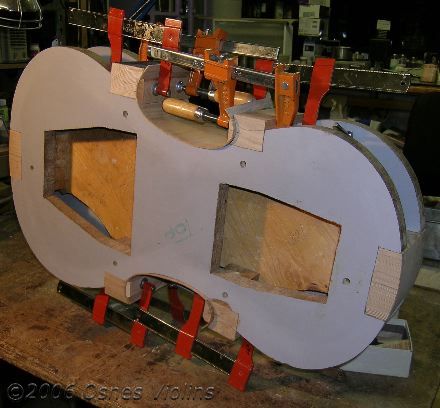

I then glue them to the blocks using counterparts to separate the clamps from the rib.

The ribs overhang the mold at this point. When the glue is dry, I remove the clamps and trim the ribs down to mold height. Then I cut the outside corners of the mold and finish the corner ready for the other ribs to be glued.

At this time I bend the remaining ribs and the linings.

Heating up a good batch of hide glue, it’s now time to glue the remaining ribs. The bottom joint is cut with a straight edge and a saw. One side is glued first, then I check the other lower bout and cut so that it fits correctly.

When dry, the maple is then trimmed to the edges of the mold. I flatten the ribs with a bit more exactness later on.

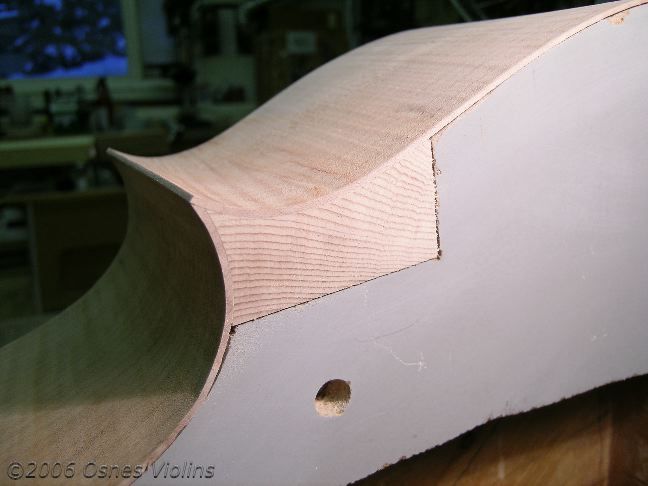

Here is a finished corner.

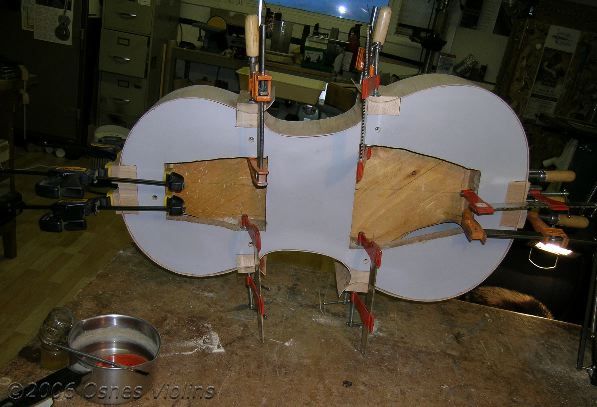

It’s time for the outside part of the mold to be removed and the linings glued in.

I just do half of the mold first to have as much strength in the assembly as possible. It is too easy to break a rib at this stage.

I inset the center linings and cut them tapering to nothing before gluing in.

I use strong hide glue for the linings.

The next pictures show my inexpensive clamping system. I am also sealing the end and corner blocks with Titebond.

I level the linings to the ribs using a knife and small planes finishing up with a sanding block.

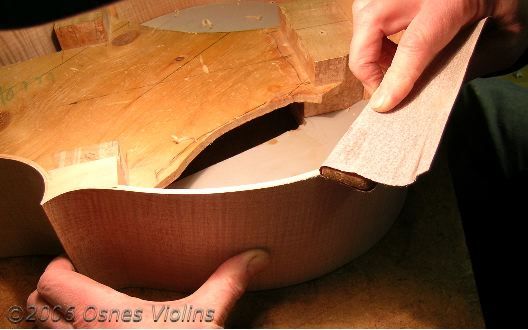

Now comes the nasty part which I didn’t fully document with fotos. The rib set needs to be level. Getting it level with the mold is part of the job. Getting it level to the flat plate finishes it. I do this with a plane and my eye. Some makers sprinkle pencil lead on the surface and rub the rib assembly on the flat surface. The high spots will be black and need to be removed by the plane.

Notice the gap under the rib. Not acceptable. Everything else must be removed until that touches. Actually, I’m not that anal. If I can get a light press fit all around I am happy...

I use a very sharp plane for this task. It takes a bit of time.

The finishing shot has me leveling the lining with a knife. I then clean it up with 180 grit sandpaper on a sanding block.

I glue strips of linen for reinforcement on the ribs. I use dilute white glue for this. I read somewhere that Stradivarius did this. There were rib cracks on the cellos where it was removed by a later technician. The cellos that weren’t touched were in fine shape.

Home

6.Top and back preparation